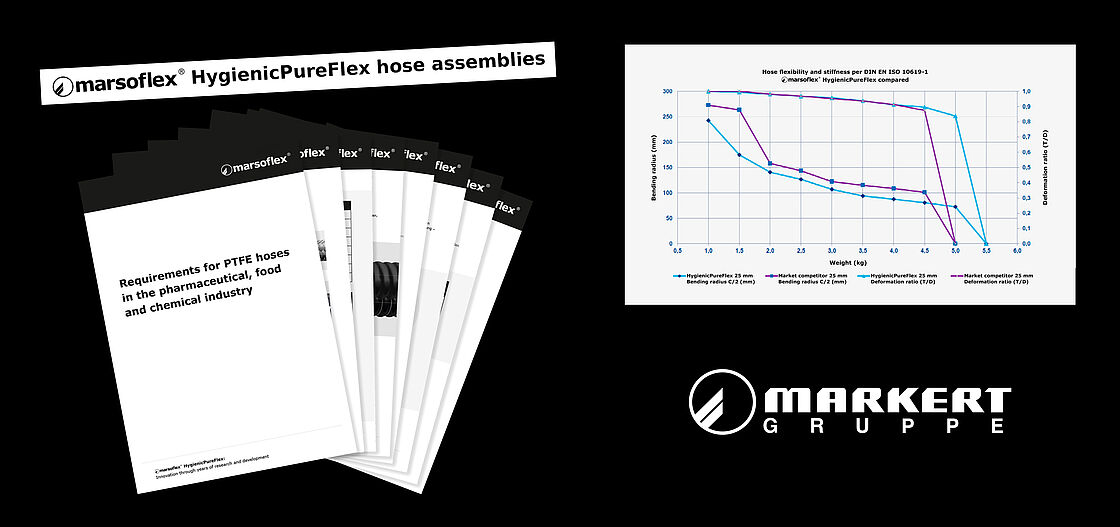

HygienicPureFlex hose assemblies: The most important points summarised for you in the white paper

Hose assemblies used in the pharmaceutical, food and chemical sectors are subject to strict requirements and must undergo approval processes. As specialists in industrial hose assemblies, it is our incentive to be among the best in the sector in this field.

Innovation made by Markert

With our HygienicPureFlex product series, we have launched an innovative hose solution for use in pharmaceutical and chemical production. One of its distinguishing features is that – unlike comparable products – it boasts full vacuum resistance even without stainless steel spirals. At the same time, HygienicPureFlex scores when it comes to durability and flexibility, as extensive tests prove.

You have questions – we provide the answers

What exactly is behind Markert's PTFE hose solution? How was it developed? What are its properties? Which test procedures do PTFE hose assemblies such as the HygienicPureFlex have to undergo in order to be approved for use in the pharmaceutical, food and chemical industries?

We explain these and many other questions in our white paper, which is available for you to download free of charge. Because we want to provide you with insights as well as convey complex background information in an understandable and transparent way.

The following points, among others, are explained in the document:

- The PTFE hose design

- Service life, flexibility and resilience of the hose assemblies

- The guidelines to be met by German and international supervisory authorities

- The demands on the material

- The connection of fittings to the hose assembly due to lining

- Mandatory cleaning procedures before first use of the hose assemblies

“Our HygienicPureFlex product series is a winner from start to finish – this is also evident from the tests that PTFE hose assemblies have to pass. In addition to many other parameters, our hose assembly solution has been tested, for example, for more than 100.000.000 load cycles.”

David Katholy, Sales Expert for Hose Assemblies in the Markert Group.

State of the Art: HygienicPureFlex

Markert can draw on its many years of research and development in the field of industrial hose assemblies. This is also how the HygienicPureFlex product series was created as an innovative PTFE hose assembly for use in pharmaceutical and chemical production. Our Specialists are of course also available for any further questions. Please feel free to contact us!